Heat Transfer Oil Filtration – An Application for FAUDI Filters

FAUDI, for example in Spain’s solar power plants Andasol and Extresol, ensures for the processing of heat transfer oils with the especially developed HTF filters. These power plants operate according to the CSP technology (concentrated solar power).

Heat Transfer Oil Filtration

HTF Filtration

After a certain period of deployment, all heat transfer oils (HTF = Heat Transfer Fluid) degenerate. This is due to thermal exposure. Low-boiling fractions of the oil vaporize during normal operation. High-boiling fractions of the oil virtually “crack” and leave behind coke-like residual material in piping and heating surfaces. These contaminants have a substantial effect upon the effectiveness of the heat transfer process and consequently also upon the heat transfer characteristic. The coking causes a change of the viscosity and the density of the oil, which in turn results in a reduction of the so-called thermal conductivity coefficient. But also the operating life of the oils and the upstream components, e. g. heat exchangers and pumps is reduced considerably. The removal of the fouling can therefore increase the effectiveness of the oil, substantially prolongate the operating life, reduce cost-intensive maintenance, and prevent complete downtimes. It also guarantees an effective and preventive protection of the system and its components. Experience has proven that, for example, the life cycle of a pump can be extended up to three times, if the contaminants are removed.

FAUDI ensures the processing of heat transfer oils with the specially developed HTF filters, for example in Spain’s solar power plants Andasol and Extresol. These power plants operate according to the CSP technology (concentrated solar power).

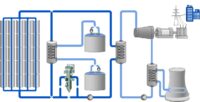

This technology comprises the transformation of sunlight into thermal energy based on the parabolic through technology. Hereby, the heat transfer oil, which generates steam via a heat exchanger, is heated up to 300° Celsius by the solar radiation. This steam then actuates the turbines and the respectively connected generators for the generation of power.

Our specially developed product

Heat transfer oil Filter

Filtration

The heat transfer oil, which has to be filtered, passes through the inlet nozzle of the filter housing and flows through the cylindrical filter elements from the outside to the inside. The contaminants deposit themselves at the exterior surface of the filter elements and form a layer. The cleaned medium flows out of the filter outlet as filtrate.

Backflushing

In the course of the filtration, the differential pressure increases due to the growing filter cake on the outer surface of the filter element. As soon as the pre-specified differential pressure is reached, the cleaning process via backflushing is initiated. The FAUDI HTF filter deploys inert gas (e. g. nitrogen) to support the backflushing process. The filter elements are flushed in pulses by internal medium pressurized by the inert gas and reverse to the filtration direction and are so effectively cleaned.

The regenerative filter elements can reach a filtration degree of down to 3 μm. As the supporting gas, nitrogen is for example well suited due to its inert characteristics. This type of gas-supported backflushing limits the backflush losses of the high-value Heat-Transfer-Fluid (HTF) to a minimum.

The HTF-Filter is an offline filter with special high-grade steel filter cartridges. The bypass-filtration guarantees for a continues filtration process.

- Improvement of the thermal conductivity coefficient

- Prolongation of the operating period of pumps and heat exchange

- Lowering of the maintenance costs

- Raise of the system availability

Why you profit

Technical Data

Medium: Heat Transfer Oil

Design pressure: 16-40 bar

Design temperature: up to 400 °C

Volume flow: 100-200 m³/h

Filter fineness: 3-100 µm

The complete production and process chain is aligned to the relevant national and international regulations and standards: ASME, ANSI, ATEX, as well as DIN ISO 9001, and others.

An overview of the advantages of the

FAUDI heat transfer oil filtration:

- Fully automatic and continuous filtration process

- Fully automatic backflush for the regeneration of the filter elements

- Minimum backflush losses due to gas-supported backflushing

- Fineness of filtration down to 3 μm

- Especially developed filter cartridges made of premium metal material to withstand highest operating temperatures

- The exclusive use of premium components and materials guarantees the long-time functional capability and reliability