Automatic filters:

Fully automatic backflush filters

(RSF F30 and RSF F32)

In numerous branches of industry and industrial applications, self-cleaning automatic filters have established themselves as process-safe and powerful filter systems of mostly low-viscosity liquids. Reasons therefore are continuous operation, low maintenance requirements and the long service life of the filter media used. Consequently, automatic backflush filters are used, for example, in water treatment (cooling water, process water, building water, wastewater, spraying water, drinking water), in the filtration of seawater, water streams in metallurgical plants and rolling mills, liquid fuels, and water-based and non-water-based cooling lubricants. The highly reliable technology and design of FAUDI fully automatic backflush filters has also been proven in the most challenging environments of numerous offshore installations.

The sizes of the two FAUDI backflush filter series are suitable for very high flow rates depending on the filter medium, the filter fineness and the type of backflushing. A modular design allows individual adaptation of the flow rate in each case from 15 m³/h to 12,000 m³/h. We are able to complement our standard sizes in welded construction as needed with project-specific products using the ideal materials, coatings and controls – all tailored to your use case or the customer specifications, standards and norms required.

Benefits: Your advantages

at a glance (RSf F30)

No filtration interruption during backflushing

Constant filtrate quality

Robust and functional design

High quality, low maintenance and low wear

Ready to use units or skids

Benefits: Your advantages

at a glance (RSf F32)

No filtration interruption during backflushing

High dirt holding capacity

Residue-free cleaning of the entire filter surface with minimized backflush volume

Low-wear and maintenance-friendly

spare parts conceptModern PLC control and/or remote monitoring

Ready to use units or skids

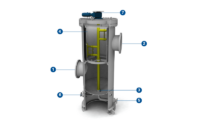

Design layout

Backflush filters (RSF F30)

The fully automatic backflush filter consists of the following components:

1. Filter inlet

2. Filter outlet

3. Flushing device (backflush arm)

4. Filter cartridges

5. Backflush outlet

6. Drain

7. Gear motor

How does a fully automatic

backflush filter work?

Filtration

The medium which has to be filtered flows through the filter elements from the inside to the outside and impurities are retained on the inside at the surface of the filter elements. Thereby, the pressure difference between the dirty and clean side of the filter elements increases.

Backflush

RSF F30 with filter elements

If the differential pressure has exceeded a set limit or a time interval has expired, the backflush filter automatically opens the backflush circuit in the cleaning unit. Due to the rotation of the cleaning unit, a partial flow of the filtered product passes through each filter element in turn from the outside to the inside and flushes the impurities from the smooth filter surface by reversing the flow. The backflush medium will be flushed out through a separate connection. During the backflushing process, the actual filtering process is not interrupted.

RSF F32 with filter cylinder

If the differential pressure has exceeded a set limit or a time interval has expired, the backflush filter automatically opens the backflush circuit in the cleaning unit. Compared to the filter element design (RSF 30), in the filter cylinder design (RSF 32) suction is applied locally through a slot in the rotating cleaning unit at a defined surface element of the filter cylinder (sequential backflushing). The backflush medium will be flushed out through a separate connection. During the backflushing process, the actual filtering process is not interrupted.

Start into your next

PROJECT WITH US now

We are your contact for engineering, piping design as well as monitoring and control.

Fully automatic backflush filters (RSF F30): Data and facts

:

Flow rates

15 – 12,000 m³/h

Filtration fineness

20 µm – 3,000 µm

Fluids

Industrial water, cooling water, seawater, emulsions, oils

Filter material

Slotted tube or wire mesh elements in stainless steel, duplex or super-duplex stainless steel