Separators: filter separators (p45)

During storage, transportation, distribution and processing of natural gas and other gaseous media, it is often necessary to clean these media by filtration and separation of solid and/or liquid contaminants. This is especially true for energy supply and here the demand for environmentally friendly, gaseous fuels will continue to increase.

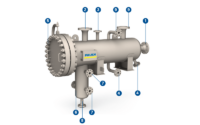

FAUDI separators and filter-separators are used for these cleaning tasks. The cleaning/separation of solid and liquid contaminants is accomplished through built-in components such as filters and/or coalescer elements, lamella packets, demisters, multi-cyclone packets or a combination of installed components. The smallest particles, fine droplets and/or aerosols are separated.

FAUDI separators are characterised in particular by being project-specific using adapted dimensions and/or materials and are thus tailored to your use case.

Benefits: YOUR ADVANTAGES

AT A GLANCE

Very fine separation of particles

and liquid dropletsSuitable for use under

extreme temperature and

pressure conditionsLow pressure loss

Sour gas design to NACE or ISO

High dirt absorption capacities

High economic efficiency

how does a

Separator work?

In FAUDI separators and filter-separators, separation usually takes place in several stages. After the gas stream enters, larger liquid droplets and coarser mechanical contaminants are separated by gravity and impact effects. Fine particles and fine liquid droplets are separated in the next stage by means of filter and coalescer elements. Depending on the application and requirements, a lamella packet or demister can be installed as a further separation stage.

The separated liquid is collected in one or in divided collecting chambers of the separator. Cyclone or cyclone packet separators use the centrifugal principle to separate solid and liquid particles from the gas flow. The separated particles and droplets collect in the lower collection chamber of the separator. With these separators, the separation efficiency depends on the density of the contamination and the flow rate.

Start into your next

PROJECT WITH US now

We are your contact for engineering, piping design as well as monitoring and control.

Industries: Where they are used

Application areas: how they are used

gas purification platform compressor station, dust collector and filter separator

FAUDI Coalescer type 45

FAUDI Coalescer type P45